Rising costs drive continuous

process improvement

Discover Line Control, an IoT-powered software. Identify opportunities for optimisation.

Save by enhancing productivity, minimising material waste, and reducing energy consumption.

Key challenges faced by the manufacturing industry:

Digitise your factory to maximise efficiency

Digital transformation is more than a trend— it’s a crucial step for manufacturing companies aiming to digitise their factories, streamline processes, cut costs, and maximise efficiency.

Implementing Line Control is a forward-thinking investment that accelerates factory digitalisation, with ROI achievable in just 6–9 months.

Discover new possibilities

In the ever-evolving world of manufacturing, where efficiency and innovation are key to success, Line Control opens up new opportunities. It enables the transition from reactive to proactive manufacturing management, utilizing real-time data for smarter decision-making.

Benefits of implementing

the Line Control system:

- Enhance efficiency and cut costs through improved utilisation of equipment and materials. Save energy and minimise waste.

- Experience timely order fulfilment with reduced labour, minimised waste, and improved quality.

- Gain real-time visibility into production performance and key data insights with advanced analytics.

- Benefit from a rapid ROI with measurable benefits, potentially within just a few months of implementation.

The future-ready software

for manufacturing

Who we are?

We are a trusted global technology partner, supporting manufacturing companies for over 10 years. We specialise in digital transformation and implementing innovative manufacturing systems, with successful projects delivered worldwide.

Our solution harnesses cutting-edge technologies, including cloud computing and IoT. With extensive expertise and in-depth industry knowledge, our skilled team delivers professional consulting and support at every stage of collaboration.

We foster lasting relationships built on trust.

Our mission is to support manufacturers in achieving success and maintaining a competitive edge..

Explore how to

optimise your production efficiency

Feature highlights

PERFORMANCE MONITORING

Real-time OEE (Overall Equipment Effectiveness) helps identify and eliminate the causes of machine downtime, improving resource utilization and boosting production efficiency.

Labour capture provides detailed insights into staff utilisation, supporting optimal team planning.

Through Performance Monitoring, our clients achieve a 20–40% increase in efficiency.

KNOWLEDGE HUB

Our advanced Knowledge and Analytics platform provides valuable input for informed decision-making. Line Control empowers employees at all levels—shop floor workers, line management, and company leaders—to gain insights into operations and manage the business efficiently.

Documentation and Specification ensures easy access to SOPs, manuals, product specifications, and more, keeping workers informed with up-to-date manufacturing guidance.

Line Control helps to reduce manufacturing costs.

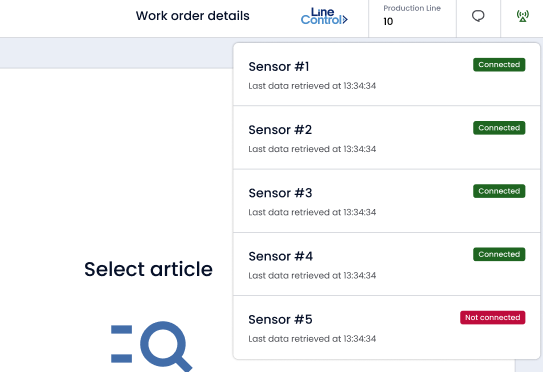

IoT DATA CAPTURE

IoT devices enable data collection on the shop floor, using sensors for efficient operation. Focus can be adapted by adding or repositioning sensors.

Installation is straightforward, allowing data on production quantities, speed, and outages to be gathered. The scope can easily be expanded to include energy usage, machine uptime, temperature, and humidity.

Shape the future of your factory with us

“Efficiency is doing things right. Effectiveness is doing the right things.“

Peter Drucker